zhiheng machine tool

Products

The company actively learns from various experiences of foreign enterprises, pays attention to every detail of machine tool design and manufacturing, and conducts in-depth and detailed research from multiple aspects such as basic material research, machine tool structural design, core component manufacturing technology, precision assembly technology, and processing application technology

Advantage

We applied electric spindles to lathes in 2006 to achieve green machine tool energy conservation, emission reduction, efficiency improvement, and cost reduction. Therefore, over the years, we have accumulated a lot of experience and exquisite technology in the field of green and environmentally friendly machine tools. We hope to become an innovative partner for our customers in this future development trend field.

Zero transmission

Remove the vibration generated by the belt

Clearing the thermal expansion and contraction errors of the belt gasket during milling

Transparent energy consumption

Water pump, hydraulic shaft machine

Adopting IE3 level or above

Greasing lubrication

Transmission part

Replacing oil lubrication with grease lubrication

Green and efficient

Electric spindle application lathe

Realize green, efficient, and energy-saving

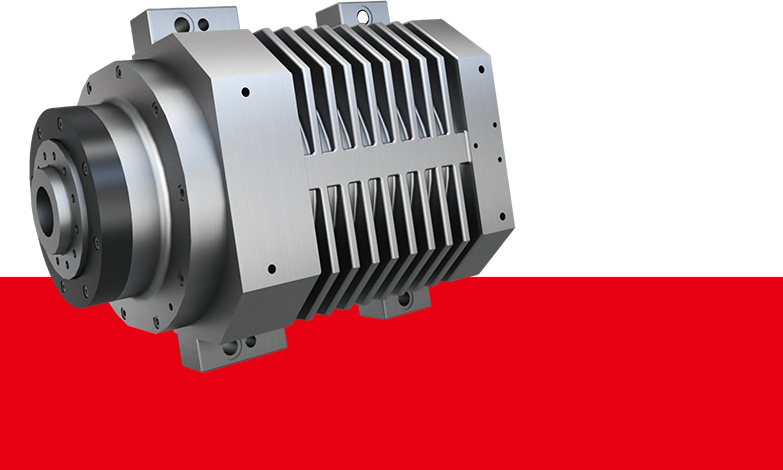

Characteristics of Electric Spindle

1. When turning and milling workpieces: under the same conditions, the electric spindle eliminates the vibration generated on the belt and the error caused by the thermal expansion and contraction of the belt during milling, as well as the error in indexing accuracy caused by buffering during linkage;

2. In terms of indexing accuracy: the indexing accuracy is 0.003 degrees;

3. In terms of cost reduction and efficiency improvement: saving 30% electricity and manpower;

4. In terms of surface roughness of processed workpieces: non-ferrous metals can reach RA0.4, and non-ferrous metals can reach RA0.8, which can achieve grinding by turning instead of grinding;

5. In terms of linkage: low-speed linkage, low-speed high torque, and 0.5 rpm stability without shaking. In terms of constant temperature technology, it can work stably for a long time;

Service

Our professional technical team provides you with pre-sales and after-sales services. Purchasing Zhiheng products not only brings a machine, but also a commitment.

Pre sales service

Professional pre-sales service personnel will provide you with detailed technical support and process plans. Based on your production needs, we provide customized models to increase production and improve quality.

After-sale service

The rapid response mechanism of professional after-sales service personnel can quickly respond to customer repair needs. A professional and high-quality after-sales service team with rich experience in production, installation, and debugging.

About Us

Zhejiang Zhiheng Machine Tool Co., Ltd., established in 2006, is a high-tech enterprise that fills the domestic gap by applying electric spindles to CNC lathes. It is a benchmark manufacturer of electric spindle turning and milling composite machine tools in China and integrates research and development, production, sales, and service.

We integrate and optimize processes to reduce subsequent secondary clamping, equipment, personnel, and manufacturing processes, providing customers with a comprehensive solution that combines electric spindle turning, milling, drilling, sharpening, and grinding processes.

News

Zhiheng Machine Tool takes you to learn more about machine tools and industry related information